- What is CNC programming?

CNC programming.(Computer Numerical Control Programming) is utilized by manufacturers to create program instructions for computers to control a machine tool. CNC is highly involved in the manufacturing process and improves automation as well as flexibility.

CNC programming.(Computer Numerical Control Programming) is utilized by manufacturers to create program instructions for computers to control a machine tool. CNC is highly involved in the manufacturing process and improves automation as well as flexibility.

Types of CNC machines

CNC programmers write instructions for CNC machines, where a computer is connected to the mill, along with electrical drives and sensors for a complete system. This computer controls the movement of the machine axis.

-

CNC programmers write instructions for CNC machines, where a computer is connected to the mill, along with electrical drives and sensors for a complete system. This computer controls the movement of the machine axis.

3-axis machining

-

The most common CNC machines produced commercially. Used for simple prismatic parts—to complex molds, medical or aerospace parts.

- The most common CNC machines produced commercially. Used for simple prismatic parts—to complex molds, medical or aerospace parts.

4-axis simultaneous

This type of machining is necessary when part geometry wraps around a part, common in the aerospace and other industries.

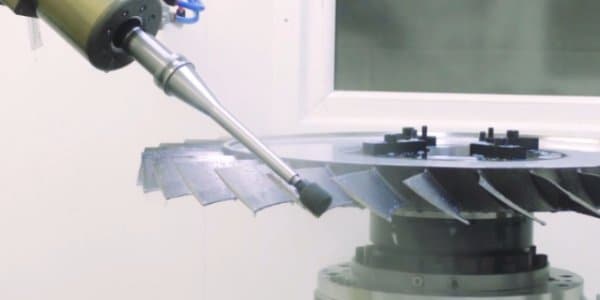

5-axis machining

Popular in parts where complex shapes and small clearances, are the norm—such as impellers, turbines, intake ports and more.

Lathe and mill turn

Lathes and mill turn machines are capable of turning a part and drilling, cutting, or carving out the shape that is needed.

No comments:

Post a Comment